If you are looking for a supplier of heat-treated grader blades in Jaipur, then look no further than our company. We offer the highest quality blades available and have been providing them to customers throughout India for years now. Our blades are made from the best materials and undergo the most rigorous of tests before they are shipped out to our customers. We know that quality is key, and we make sure that every blade we sell is up to top quality parameters. If you are interested in learning more about our blades or in finding a reliable supplier of heat-treated grader blades in Jaipur, please do not hesitate to contact us today.

Heat Treated Grader Blades Manufacturer and supplier in Jaipur

What is a Heat Treated Grader Blade?

A heat-treated grader blade is a type of agricultural tool that is used to smooth the surface of a field or other ground. It is also referred to as a soil smoother, aggradator, or terraformer. The blade is heated to a high temperature and then used to burnish the earth’s surface.

Types of Heat-Treated Grader Blades

There are different types of heat-treated grader blades which can be broadly classified into three types according to the manner in which they are heat treated. The first type is the quenching and tempering type, in which the blade is quenched in oil or water and then heated until it reaches its hardening temperature. The second type is the induction heating type, in which the blade is heated by induction coils. The third type is the arc heating type, in which a wire arc melts and hardens the metal around it.

The advantages of using a heat-treated grader blade over an untreated one are manifold. Firstly, the blade will last longer because it will not wear out as quickly due to its increased resistance to wear and tear. Secondly, it will provide better results because it will cut more smoothly and precisely. Finally, it will be less likely to catch fire due to its increased fire resistance.

Why use heat-treated blades?

The popularity of heat-treated blades has many reasons. The blades are made to outperform standard blades and last longer. The process of heat treating the blade ensures that it is tough, durable, and can take a lot of punishment before it fails. Additionally, the process also makes the blade harder to sharpen and reduces wear on the tooling.

Advantages and Disadvantages of Heat-Treated Grader Blades

Heat-treated grader blades are a specialized type of blade that is designed to resist wear and tear. This type of blade is also known as a hardened steel blade. The main advantage of heat-treated grader blades is that they last longer than regular grater blades. They also have a higher resistance to wear and tear, which makes them ideal for use on hard surfaces, such as stone or concrete.

However, there are some disadvantages associated with using heat-treated grader blades. First, they can be more expensive than regular grater blades. Second, they can take longer to sharpen than regular grater blades. Finally, they may require more care when using them because they are more susceptible to damage.

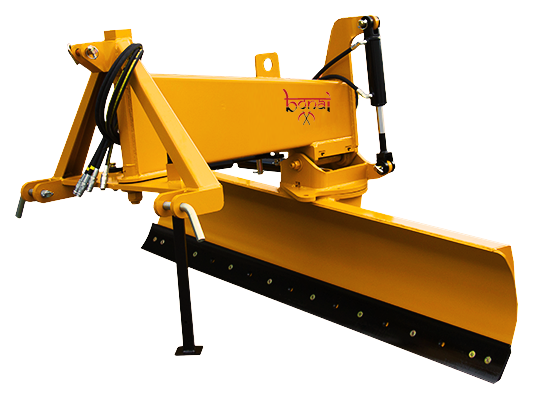

Bonai India Grader Cutting Edge Nut Bolt Manufacturer

Bonai India Grader cutting edge nut bolt manufacturer and supplier is one of the leading manufacturers of heat-treated grader blades in Jaipur. The company offers a wide range of heat-treated grader blades that are designed to meet the specific requirements of various industries. The company also manufactures other related products such as nut bolts, washers, and other associated components.