Grader Cutting Edge Blade Supplier and Manufacturer in India

A Grader Cutting Edge Blade is a specialized type of blade that is used for cutting and leveling of soil. It’s designed to provide precision and accuracy when working with difficult-to-cut materials, such as stones, WMM, coal mines, iron ore mines etc.

The blade is made from high-quality carbon steel, which makes it resistant to wear and tear. It also has a sharp edge that stays longer for rough use. This ensures that you get accurate cuts every time, no matter how challenging the material may be.

Overall, a Grader Cutting Edge Blade is an essential part of Motor Grader. It provides precise and accurate cuts, making it easier than ever to get the job done right.

Why are Grader Blades important?

The benefit of using a sharp grader blade to cut and shape is that the edges are always smooth. This means that there is less chance of chipping or breaking, and the finished product will be more accurate. Additionally, a dull grader blade can cause more damage when shaping, as it will create burrs on the surface of the soil, stone or minerals.

The purpose of the Grader Cutting Edge Blade

Road grading is a method of maintaining and leveling an unpaved road surface. Road grading is essential before a road is paved or for permanent dirt/gravel roads.

When vehicles drive on an unpaved road, the surface material can become displaced, causing potholes, washboard bumps, and uneven surfaces. Roads that are not properly maintained have an increased risk of accidents and are more susceptible during wet or icy conditions. Shaping the road surface is also crucial for proper drainage, salt/sand distribution, and controlling surface moisture. Road grading results in safer roads with improved traction, proper drainage, and better driving conditions.

Summer Road Maintenance (Road Building & Maintenance)

- A thin blade and sharp edge can penetrate soft ground material with little to no down pressure – which saves you time and reduces fuel expenses.

- A thin and flat blade can be used to cut and reshape the road as well as pull ditches – which will reduce the amount of future road maintenance and increase flexibility.

- A serrated blade can penetrate the ground and bring up more materials to distribute over potholes and wheel ruts – which can reduce future maintenance and get the job completed in less passes

- A corrugated style blade will allow vegetation, fines, and roughage to flow through the holes of the blade – which creates a good mix of surface materials for the roadbed. This style of blade also gives the best cut because it refreshes as it wears, similar to scarifier teeth.

- A flat or curved blade will roll the material along the face of the blade which mixes the fines and redistributes them evenly across the road.

Winter Road Maintenance (Ice & Snow)

- Corrugated, scarifier, or thin grader blades allow operators to easily cut through the ice to remove it with very little down pressure – which saves you time and reduces fuel expenses

- Grader blades can push snow packs while breaking through the frozen ground – which allows sand or salt to react with the surface much quicker.

- Road grading will open up the road surface allowing for grooves that keep salt or sand from being blown off the road by wind or traffic – which reduces your costs on salt/sand while keeping drainage cleaner.

- Thin and sharp grader blades reduce friction and heat – which can otherwise cause the road to become slippery or refreeze as ice patches.

- BluSteel cutting edges reduce the downward pressure required – which allows operators better traction without tire chains.

How can I use the blade?

The Grader Cutting Edge Blade is perfect for cutting and shaping soil levelling. This blade is made from high-quality steel and has a sharp edge that makes it easy to cut through stones. The blade also has a serrated edge that helps to slice through stone more easily.

The Grader Cutting Edge Blade can be used for a variety of tasks, such as cutting shapes out of stone, road grading, and even creating rabbets. Because the blade is made from high-quality steel, it will stay sharp and will not wear out quickly. Additionally, the serrated edge helps to make slicing through stone easier.

Types of Grader Blades

There are numerous types of grader blade cutting edges, including:

- Flat:Flat blades exhibit maximum strength and high impact and abrasion resistance, making them ideal for road maintenance. They are best suited for applications where materials do not need to be carried or redistributed.

- Curved: These replacement grader blades deliver optimal penetration, material flow and rolling action, meaning they are beneficial for fine grading and finishing applications. They are used when materials require top-layer redistribution to create a finished road surface.

- Serrated:It is best to use serrated grader blades when ground penetration is necessary to move surface materials. They are excellent for piercing ice, snow and gravel.

- Carbide:Carbide blades are ideal for high-abrasion, low-impact tasks. They offer better wear properties than steel varieties.

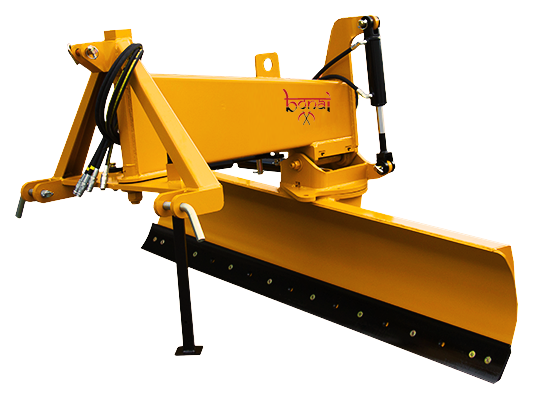

At BONAI INDIA, we carry an extensive variety of state-of-the-art replacement grader blades from our manufacturing facility at Greater Noida, UP, India. When you purchase grader blade cutting edges from us, you can feel confident that you will get wear parts representing the market’s best in quality and performance.

Bonai India manufacture the following Blades:

- Heat Treated Grader Blades

- High Carbon Grader Blades

- Grader Cutting edge 5D-9553

- Grader Cutting edge 5D-9554

- BEML Grader Blades

- XCMG Grader Blades

- CASE Grader Blades

- Motor Grader Cutting Edge

- Grader Cutting edge

- Grader cutting edge nut bolt

- Grader blade Nut Bolt

- Caterpillar Grader Blades

- Komatsu Grader Blades