Heat Treated Grader Blades Supplier in Guwahati

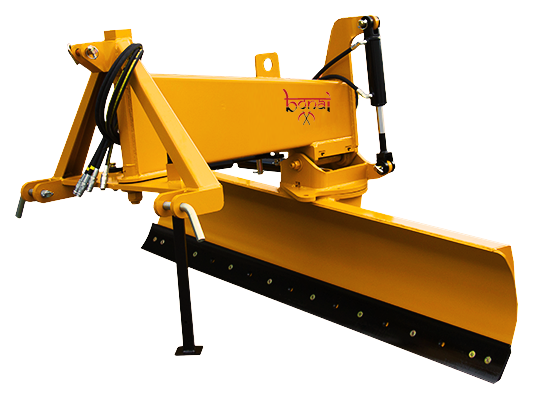

Looking for a supplier of heat-treated grader blades in Guwahati? Look no further! At Bonai India, we specialize in supplying high-quality heat-treated grader blades to customers all over the world. We offer a wide range of grades, from standard to extra-hard, and our blades are made to withstand the toughest conditions. Contact us today to learn more about our products and services,

What is a Heat Treated Grader Blade?

Heat treated Steel grader blades can help operators meet the needs of any road grading or earthmoving application. Heat treated Steel blades are inexpensive options that are designed to provide excellent wear life and efficient performance. BONAI INDIA offers a wide variety of high-quality heat-treated steel grader blades. We offer both flat and curved steel graders blades with or without serrated teeth in a range of dimensions.

Uses of a Heat-Treated Grader Blade

You can use grader blade parts for a wide range of industrial applications depending on the blade size you choose. Common uses for grader blades include:

- Road Construction

- Landscaping

- Road maintenance

- Grounds keeping

- Ditching

- Sports field maintenance

- Driveway reconditioning

- Drain cutting

Types of Heat-Treated Grader Blade

- Flat Edges – best suited for applications when the material does not need to be carried to be redistributed and for ditching or general gravel maintenance.

- Serrated Edges – best suited for applications when increased ground penetration is required to move surface materials.

- Curved Edges – best suited for applications when existing material is carried and redistributed along the top layer to create a smooth and flat finished road surface.

- Scarifier Edges – best suited for applications when the ground is heavily compacted, contains heavy rocks, is paved with asphalt or has heavy ice.

How to Choose the Right Heat-Treated Grader Blade

Matching your grader blade with your operating conditions and desired grading outcomes will have a significant impact on productivity, grade quality, and the stresses placed on your machine.

When selecting your grader blade, ensure you consider its length, width, thickness, hardness, whether it should be curved or flat, and whether it should be serrated.

Grader Blade Length

The length of your grader blade should be determined by the size and configuration of the machine it is being fitted to. Most graders require two grader blades, with six, seven or eight-foot blades being the most common.

Grader Blade Width

The width of your grader blade is a key determinant of how well it wears. The standard width is six inches, however eight inches is also a popular width for those seeking increased wear life. There are also less common 10-inch grader blades, as well as the option to produce custom widths for those with unique requirements.

Grader Blade Thickness

Like width, the thickness of your grader blade is a key wear property. The standard grader blade thickness is 5/8-inch, while 3/4-inch and 1-inch thicknesses are also available if your operating conditions require extra wear material.

However, consider that increased blade thickness will also increase blade weight, make ground penetration more difficult and place unnecessary stresses on your machine’s drive train and frame components, so it is important not to choose a thicker blade that an application requires.

Lastly, thinner, curved blades are best suited for a final trim.

Curved or Flat Grader Blades

- Curved grader blades: are best used for applications requiring a penetration and rolling action and are best suited for fine grading and finishing work where a high degree of accuracy and quality are required.

- Flat grader blades: are best suited to heavy road maintenance where the shaping of the road surface is not critical. Their strength and extra wear material make them the preferred option for applications where abrasion and impact resistance are required.

Serrated Grader Blades

Designed to penetrate packed gravel, serrated grader blades deliver better penetration than a continuous edge thanks to increased pressure-per-inch of edge contact. Serrated blades are available in both curved and flat edge styles.

Grader Blade Hardness

A harder grader blade will generally offer better wear protection properties. However, consider that harder grader blades may be more brittle and susceptible to cracking if you hit a large rock during grading. If this occurs the grader blade must be replaced, so it is important to strike a balance between hardness and impact resistance, and choose a supplier who can deliver a grader blade with both.

The two most common methods of hardening grader blades are:

- Heat treated grader blades which offer through-hardness of 420-512 Brinell BHN

- Black, high carbon steel grader blades which offer through-hardness up to 320 Brinell

Mahindra Grader Blades Manufacturers

Bonai India Mahindra Grader Blades manufacturers are one of the leading suppliers of grading blade systems in the world. We offer a range of products that cater to the needs of different industries, including agriculture, construction, mining, and energy. We have a strong reputation for quality and reliability, which has helped it grow into one of the leading providers of grading blade systems. Bonai India Mahindra Grader Blades manufactures blades using state-of-the-art technologies that ensure consistent performance and accuracy. Their blades are also designed to protect workers from injury.