Heat Treated Grader Blades Supplier in Hyderabad

Heat-treated grader blades are ideal for construction applications. The blades are made using a heat treatment process that makes them resistant to wear and tear. This ensures long life and reliability for the equipment that uses them.

What are Heat Treated Grader Blades?

Heat-treated grader blades offer many benefits over traditional blades. These blades can withstand high temperatures, which makes them ideal for use on hot surfaces. They also have a longer lifespan and are less likely to rust.

Types of Grader Blades

Curved or Flat Grader Blades

- Curved grader blades are best used for applications requiring a penetration and rolling action and are best suited for fine grading and finishing work where a high degree of accuracy and quality are required.

- Flat grader blades are best suited to heavy road maintenance where the shaping of the road surface is not critical. Their strength and extra wear material make them the preferred option for applications where abrasion and impact resistance are required.

Serrated Grader Blades

Designed to penetrate packed gravel, serrated grader blades deliver better penetration than a continuous edge thanks to increased pressure-per-inch of edge contact. Serrated blades are available in both curved and flat edge styles.

Heat Treated Grader Blades specifications

The blades on a heat-treated grater are made out of high-quality and hardened steel. The two most common methods of hardening grader blades are:

- Heat treated grader blades which offer through-hardness of 420-512 Brinell BHN

- Black, high carbon steel grader blades which offer through-hardness up to 320 Brinell

This process makes the blade incredibly strong, and able to withstand a lot of wear and tear.

How to Choose the Right Heat-Treated Grader Blade?

When it comes to choosing the right heat-treated grader blade, there are a few things to consider.

The first thing to consider is the material being graded. If the material is hard, then a harder grade of the blade will be needed. On the other hand, if the material is soft, a softer grade of the blade will be more appropriate.

Another thing to consider is the shape and size of the object being graded. If the object is large and irregular in shape, a blade that can handle that kind of variation may be necessary. Likewise, if the object is small and uniform in shape, a blade that can cut quickly through that type of material may be appropriate.

The Benefits of Heat-Treated Grader Blade

Heat-treated grader blades offer many benefits over their untreated counterparts. Not only are they stronger, but they also resist wear and tear, providing longer blade life. They are also less likely to corrode, meaning that your equipment will last longer. In addition, heat-treated grader blades are less susceptible to rust and corrosion, meaning that you can operate your equipment in harsher environments without fear of damaging it.

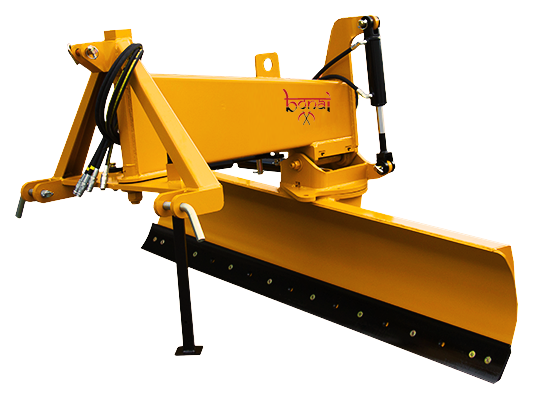

Grader Cutting Edge 5D-9553, 13 Hole Supplier

Bonai India known as Grader Cutting edge 5D-9553, 13 Hole Suppliers is a reliable supplier of grader blades across any region of India. Our 5D-9553 Grader curved Cutting Edge is designed for accurate and consistent grading. It has a precision ground cutting edge that results in even cuts, making it ideal for use with various materials. The 5D-9553 Grader Cutting Edge is also easy to operate, making it perfect for both experienced and novice users. Contact us today to learn more about our Bonai India Grader Cutting edge 5D-9553 Supplier.