Heat Treated Grader Blades Supplier in Jaipur

Heat-treated grader blades are a crucial part of any manufacturing process. They’re used to smooth out materials and reduce the amount of material that needs to be cut, thereby saving time and money. Construction Contractors rely on these blades to ensure that the quality of their products is top-notch. Unfortunately, they can also be damaged during production. In this blog post, we will explore the different types of heat-treated grader blades and how you can protect them from damage. By doing so, you can ensure that your machine process runs smoothly and with minimal losses.

What is a Heat Treated Grader Blade?

A Heat Treated Grader Blade is a type of cutting instrument that is used for grading, smoothing, and rounding surfaces. Heat-treated grader blades offer many benefits over traditional blades. These blades can withstand high temperatures, which makes them ideal for use on hot surfaces. They also have a longer lifespan and are less likely to rust.

Different Types of Heat-Treated Grader Blades

There are numerous types of grader blade cutting edges, including:

- Flat:Flat blades exhibit maximum strength and high impact and abrasion resistance, making them ideal for road maintenance. They are best suited for applications where materials do not need to be carried or redistributed.

- Curved: These replacement grader blades deliver optimal penetration, material flow and rolling action, meaning they are beneficial for fine grading and finishing applications. They are used when materials require top-layer redistribution to create a finished road surface.

- Serrated:It is best to use serrated grader blades when ground penetration is necessary to move surface materials. They are excellent for piercing ice, snow and gravel.

- Carbide:Carbide blades are ideal for high-abrasion, low-impact tasks. They offer better wear properties than steel varieties.

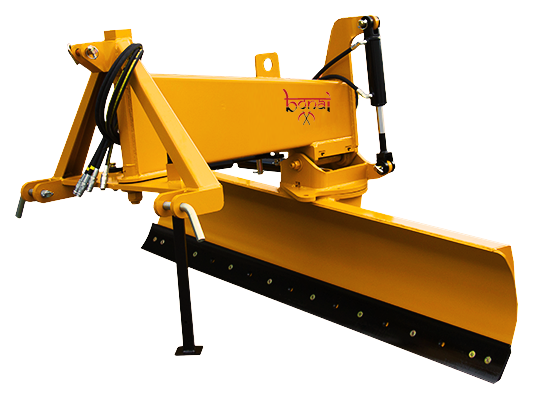

At BONAI INDIA, we carry an extensive variety of state-of-the-art replacement grader blades from our manufacturing facility at Greater Noida, UP, India. When you purchase grader blade cutting edges from us, you can feel confident that you will get wear parts representing the market’s best in quality and performance.

How to Choose the Right Type of Heat-Treated Grader Blade

Matching your grader blade with your operating conditions and desired grading outcomes will have a significant impact on productivity, grade quality, and the stresses placed on your machine.

When selecting your grader blade, ensure you consider its length, width, thickness, hardness, whether it should be curved or flat, and whether it should be serrated.

Grader Blade Length

The length of your grader blade should be determined by the size and configuration of the machine it is being fitted to. Most graders require two grader blades, with six, seven or eight-foot blades being the most common.

Grader Blade Width

The width of your grader blade is a key determinant of how well it wears. The standard width is six inches, however eight inches is also a popular width for those seeking increased wear life. There are also less common 10-inch grader blades, as well as the option to produce custom widths for those with unique requirements.

Grader Blade Thickness

Like width, the thickness of your grader blade is a key wear property. The standard grader blade thickness is 5/8-inch, while 3/4-inch and 1-inch thicknesses are also available if your operating conditions require extra wear material.

Benefits of Using Heat-Treated Grader Blades

There are a number of benefits to using heat-treated grading blades. Firstly, these blades resist wear and tear better than traditional blades, meaning that they can last longer before needing to be replaced. Finally, heat-treated grading blades are less likely to cause any damage to the materials that they are grading, meaning that they are less likely to create discrepancies between the quality of the material that they are cutting and the quality that was intended.

Grader Cutting Edge 5D-9554, 15 Hole Supplier

The Bonai India known as Grader Cutting edge 5D-9554, 15 Hole Supplier offers a wide range of products that can be customized according to the needs of the customers. The products are made using quality-assured materials that ensure durability and accuracy.