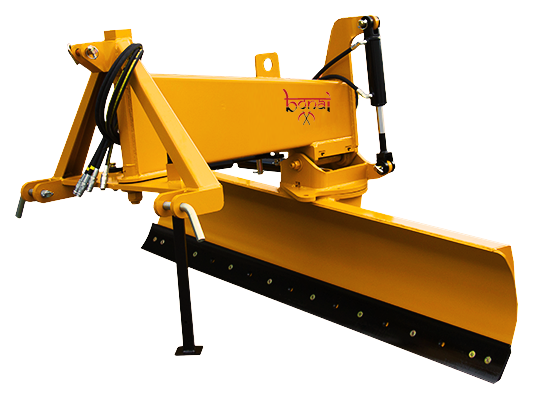

Motor Grader Blades Manufacturer and supplier in Bangalore

A motor grader is a construction machine with a long, horizontal blade at the front that is used to create a level surface. The blade is operated by hydraulic rams that can raise, lower, and tilt it. Motor graders are also equipped with a cab so the operator can have a clear view of the work area.

What are the benefits of Motor Grader Blade?

Motor grader blades manufacturer in Bangalore, India. Bonai Engineering PVT. LTD. Manufacture and supply motor grader blades and other earthmoving equipment parts to customers all over the India.

Motor Grader Operating and Maintenance Tips

Motor Graders are one of the most versatile machines used in construction and maintenance. Though their primary function is to level andgrade surfaces, they can also be used for many other tasks such as removing snow, digging trenches, and spreading gravel.

Due to the nature of their work, motor graders are subject to a lot of wear and tear. In order to prolong the life of your machine and avoid costly repairs, it is important to follow some basic operating and maintenance tips:

- Inspect the blades before each use – Check for cracks, chips or damage. Replace any damaged blades with new ones from your trusted supplier.

- Keep the blades sharp – A sharp blade will cut through material more easily, resulting in a smoother finish. Use a file or grinder to keep the edges sharp.

- Be careful when using on frozen ground – The blade can easily slip on icy surfaces, so take extra care when operating in these conditions. Slow down and make shallower passes if necessary.

- Clean the machine after each use – Remove all dirt and debris from the grader body and blades. This will help prevent rusting and other damage.

Uses of motor graders on farms?

Motor graders are one of the most versatile tools on a farm. They can be used for a variety of tasks, such as leveling fields, digging trenches, and clearing debris.

Farmers often use motor graders to level fields before planting. This ensures that the seeds are planted in an even layer, making it easier for them to germinate and grow. Motor graders can also be used to clear debris from fields, such as rocks and roots. This helps the plants to grow without being hindered by obstacles.

Trenches are another common use for motor graders on farms. These can be used to irrigation ditches or drainage channels. By digging trenches, farmers can ensure that water flows where they want it to go, and that excess water is removed from the field. This prevents flooding and helps the crops to stay healthy.

What are the Benefits of Using a Motor Grader Blade?

Motor grader blades are an essential piece of equipment for any construction or landscaping project. There are many benefits to using a motor grader blade, including:

- Increased productivity – A motor grader blade can help you complete your project faster and more efficiently.

- Improved accuracy – With a motor grader blade, you can achieve a higher level of precision and accuracy when grading or leveling surfaces.

- Greater versatility – A motor grader blade can be used for a variety of tasks, such as clearing debris, grading gravel roads, and digging trenches.

- Reduced operator fatigue – The operator of a motor grader will experience less fatigue thanks to the machine’s ergonomic design and comfortable controls.

How to Select Motor Grader Blades?

There are a few things to keep in mind when selecting motor grader blades. The size of the blade is important to consider. The blade needs to be big enough to do the job, but not so big that it’s difficult to control. Another thing to think about is the type of steel used. Some steels are better suited for certain applications than others. Finally, cost is always a factor. You want to get the best value for your money.

When it comes to size, the first thing to consider is the width of the blade. The wider the blade, the more material it can move. But wider blades can also be more difficult to control. If you’re not experienced with using a motor grader, it’s probably best to stick with a narrower blade. As for the length of the blade, that will depend on what you’re using it for. If you’re just doing light duty work, a shorter blade may be fine. But if you’re going to be doing a lot of grading, you’ll need a longer blade so you can cover more area in one pass.

As for the type of steel used, there are several different options. Each has its own advantages and disadvantages. For example, high carbon steel is very strong and durable but it can rust quickly if it’s not properly maintained. Stainless steel doesn’t just as easily but it’s not as strong as high carbon steel.

We are one of the leading motor grader blades manufacturer in Bangalore. We offer a wide range of products and services to meet your needs. Our team is dedicated to providing you with the best possible experience, and we’re always here to answer any questions you may have. Contact us today to learn more about our products and how we can help you get the most out of your motor grader.