Motor Grader Blades manufacturer and Supplier in Mumbai

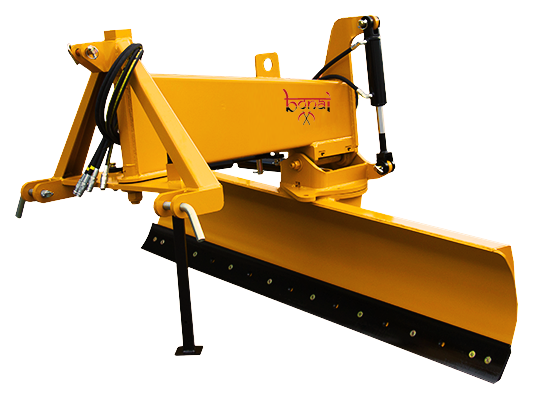

Motor graders are heavy equipment used for grading and leveling earth surfaces. The blade is the most important part of the motor grader as it is responsible for performing the majority of the work. Motor grader blades come in a variety of sizes and shapes, depending on their intended use. The most common type of motor grader blade is the double bevel curved, which is used for leveled dirt roads or other flat surfaces.

A double bevel curved blade is a long, curved blade that is attached to the front of the motor grader. The blade can be adjusted to different angles and positions to control how much material is moved and how it is graded. The operator controls the blade with a series of levers inside the cab.

The other main type of motor grader blade is called a scarifier. Scarifies are shorter and have teeth or cutting edges that are meant to loosen up compacted materials like asphalt or concrete. Scarifies can also be used to remove vegetation from an area before grading begins.

Different Types of Motor Graders-

There are different types of motor graders. Each type has its own advantages and disadvantages. The most common types are:

1) Pneumatic tire motor graders: These are the most popular type of motor graders. They are versatile and can be used on a variety of surfaces. However, they are not as maneuverable as other types of motor graders and can be difficult to operate on soft or uneven surfaces.

2) Articulated motor graders: These graders have a hinge in the middle that allows them to turn more sharply than pneumatic tire graders. They are also more maneuverable and can be easier to operate on soft or uneven surfaces. However, they are not as stable as pneumatic tire graders and can tip over if not used carefully.

3) Crawler-mounted motor graders: These graders have tracks instead of wheels, which makes them more stable and able to operate on rougher surfaces. However, they cannot turn as sharply as other types of motorgraders and can be difficult to maneuver in tight spaces.

How Do Motor Graders Work?

A motor grader is a construction machine with a long, horizontally mounted blade. The blade is used to create a flat surface during grading operations. The grader’s operator controls the height of the blade and its angle of attack to achieve the desired result.

The motor grader’s blade is mounted on a frame that sits atop four large wheels. The frame can be raised or lowered to adjust the blade’s height. The frame can also be tilted from side to side, which changes the angle of attack of the blade.

Most motor graders have two sets of controls: one for each direction in which the machine can travel (forward or backward). This arrangement allows the operator to grade while traveling in either direction. Some motor graders have an additional set of controls that allow the operator to raise and lower the frame independently of the direction of travel.

Some motor graders are equipped with hydraulic ripper shanks. These shanks can be lowered to loosen packed material, such as asphalt, prior to grading. Ripper shanks can also be used to break up large clumps of dirt and debris.

FAQs

What is the primary function of a motor grader?

The primary function of a motor grader is to level and grade surfaces during construction projects. It can also be used to remove snow, clear debris, and perform other tasks related to road maintenance.

How does a motor grader work?

A motor grader consists of a long blade that is mounted on a frame and attached to the front of a tractor or other vehicle. The operator uses hydraulic controls to raise and lower the blade as well as tilt it from side to side. This allows the machine to create a smooth, level surface.

What are the different types of blades that can be used on a motor grader?

There are several different types of blades that can be used on a motor grader, depending on the specific application. Some common options include curved blades, straight blades, winged blades, V-blades, and scarifier teeth.

How do I choose the right type of blade for my project?

The type of blade you need will depend on the nature of your project. For instance, if you’re working with loose materials like gravel or sand, you’ll want to use a straight blade. If you’re dealing with harder materials like asphalt or concrete, you’ll need a more specialized blade such as a V-blade or scarifier tooth. Talk to your motor grader dealer or supplier to find out which option is best.